Pumshini we-lastic thermoforming ungumshini odonsa i-PVC eshisiwe neyipulasitiki eyenziwe ngepulasitiki, i-PE, i-PP, i-PET, i-HIPS namanye amakhoyili epulasitiki e-thermoplastic abe yizimo ezihlukahlukene zamabhokisi okupakisha, izinkomishi, amathreyi neminye imikhiqizo.

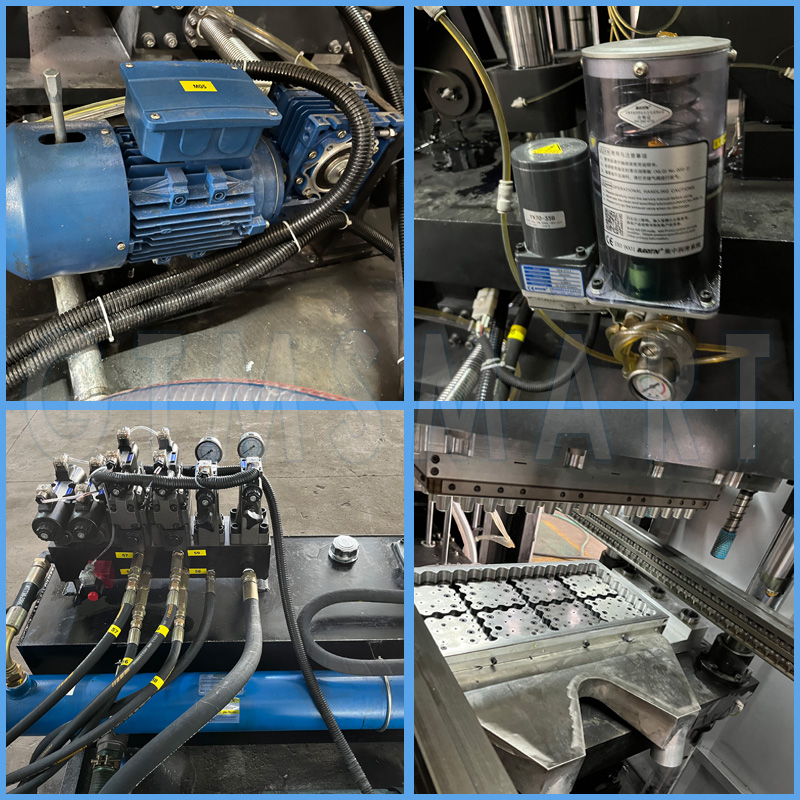

Umshini we-thermoforming osebenza kahle kakhulu uthola ukusebenza kahle, umsindo ophansi nokusebenza kahle okuphezulu.

Ukugeleza Kwenqubo

Ukugeleza kwenqubo yonke yezinto zayo zokusebenza yilokhu:

① Isiteshi sokushisisa

Yakhiwa amaziko kagesi aphezulu naphansi, isilawuli se-PID sokulawula izinga lokushisa lokulawula ukuxhumana kwe-Modbus, ukufeza ukushisa okunembayo okuphezulu.

② Ukwakha isiteshi

I-Servo ilawula ukubumba amapuleti omhlahlandlela angaphezulu naphansi kanye namapuleti anwebekayo, kanye nevalvu evuthela umoya, i-vacuum valve kanye ne-back blowing valve, idlala indima yokubumba ipulasitiki futhi iyingxenye eyinhloko yomshini.

③ Isiteshi sokubhoboza

I-Servo ilawula amapuleti angumhlahlandlela angaphezulu naphansi ukuze ashaye, futhi ibambisane ne-valve yokukhipha imfucuza ukuze ibhoboze izimbobo futhi isuse imfucuza yokubhoboza.

④ Isiteshi sokusika

I-Servo ilawula ukusika amapuleti omhlahlandlela angaphezulu naphansi kanye nesisiki, esidlala indima yokusika imiphetho namakhona kanye nokuhlukanisa imfucuza yomkhiqizo.

⑤ Isiteshi sokupakisha

I-Servo ilawula ukusunduza, ukubamba, phezulu naphansi, ngaphambili nangemuva, nokuzungezisa izingxenye ezinhlanu zemishini ukuze ibone ukupakishwa nokudlulisa imikhiqizo eqediwe ngezindlela ezine ezihlukene.

Izinzuzo

- Ukukhiqizwa kwesivinini esikhulu kanye nokwenza ngcono ukusebenza kahle

Imulti-station umshini thermoforminginomthamo omkhulu wokukhiqiza izikhathi ezingaba ngu-32 ngomzuzu wento ethile kanye nesikhunta. Manje hlukanisa futhi ubale isikhathi sesinyathelo ngasinye kumjikelezo wokubumba, lungiselela ukuxhumana phakathi kokubumba kanye nesenzo sokudlulisa ithebhu yokudonsa, wandise ukusebenza kahle, futhi ukhuphule izinga lokushisa ukuze unciphise isikhathi sokushisa. Ngokwesisekelo semikhiqizo eqediwe efanelekayo, yonke iminithi Ingafinyelela izikhathi ezingaphezu kwezingu-45.

- Ukulungiswa okuzenzakalelayo kwesiteshi

Ngobude obuhlukile bokudonsa-ithebhu, ibanga phakathi kweziteshi lingalungiswa ngokuzenzakalelayo. Ngemva kokufaka ubude bangempela bethebhu yokudonsa noma umsebenzi wefomula ukuze ufunde ubude bethebhu yokudonsa, isistimu izobala ngokuzenzakalelayo ibanga phakathi kweziteshi.Uma kungekho ukulungiswa kahle, kuqinisekiswa ukuthi isikhundla se-die cutter siyavumelana, futhi isiteshi sokupakisha siqondaniswe ngokunembile.

- Isivinini sokuphendula esisheshayo sokulawula ibhasi

Ukusetshenziswa kokulawula ibhasi kuthuthukisa kakhulu isivinini sokuphendula uma kuqhathaniswa nendlela yokuxhumana evamile, futhi kwenza izintambo zibe lula ukuze amakhasimende akho abe lula.

- Umsebenzi wesikrini sokuthinta kulula ukuwusebenzisa

Uhlelo lwesikrini sokuthinta lunemisebenzi enamandla, efana nesixhumi esibonakalayo se-wechat, okulula ukusiqonda, ukusebenza kalula, esilungele ukusebenza kwefomula nokushaya ucingo, futhi idatha yefomula ingangeniswa futhi ithunyelwe ngaphandle.Umthwalo womsebenzi wenziwa lula, futhi amapharamitha okwakha asethwa neshadi lokuzulazula eksisi yesikhathi ukuze kugwenywe umthelela obangelwa ukulungiselelwa kwesikhathi esingafanele.

I-GTMSMART inochungechunge lwemishini ye-thermoforming ephelele, njengeUmshini Olahlwayo We-Cup Thermoforming,Umshini Wokugcwalisa Iziqukathi Zokudla Zepulasitiki,Umshini Wokushisa Wembiza Yezimbali Yepulasitiki, njll. Besilokhu silandela imithetho yokumisa yenqubo yokukhiqiza eqinile, songa isikhathi nezindleko zazo zombili izinhlangothi futhi sikulethela izinzuzo ezinkulu.

Isikhathi sokuthumela: Feb-23-2022